Wireless Vibration Monitoring System

Wireless vibration monitoring system. Banners wireless vibration monitoring solutions make it easy and cost effective to monitor a variety of vibration characteristics. With wireless vibration monitoring the sensor tracks and records vibration level measurements used to determine the health of rotating machinery such as compressors and pumps drive motors driven devices and belts gears shafts bearings and other components that make up a mechanical system. The AMS Wireless Vibration Monitor delivers full vibration data over a self-organizing wireless mesh network.

You can closely monitor any piece of equipments static dynamic vibration analysis and differential process and vibration data from anywhere around the globe. Overall vibration PeakVue measurements and temperature readings can be easily integrated into any control system or plant historian while. The Protect Wireless remote vibration monitoring equipment and monitoring system provides everyone with the ability to conduct wireless vibration analysis.

As an additional value our Wireless Vibration Sensor have a built-in integrator as a result it can internally calculate velocity parameters for alarms. Phantom is a wireless vibration monitoring system that integrates other parameters such as temperature current RPM and speed into a single diagnostic system. Vibration Monitoring Systems Wireless.

Tracking excess vibration in rotating equipment is critical to identifying machine faults early so maintenance teams can keep plants and facilities up and running. With 12 independent RF bands and over 400 points per receiver the system can monitor over 5000 points even within the same RF coverage area. We are proud to provide you with.

The RecovibTiny is a 3-axis shock vibration data logger. With wireless vibration monitoring Yokogawa offers regular updates in a fast and cost-effective manner allowing for a more predictive maintenance routine. Many existing plants still rely on manual sampling for vibration monitoring.

What is a Wireless Vibration Monitoring System. It measures automatically vibration in three directions as well as the bearing temperature. It provides rich information about machinery health for both operations and maintenance personnel.

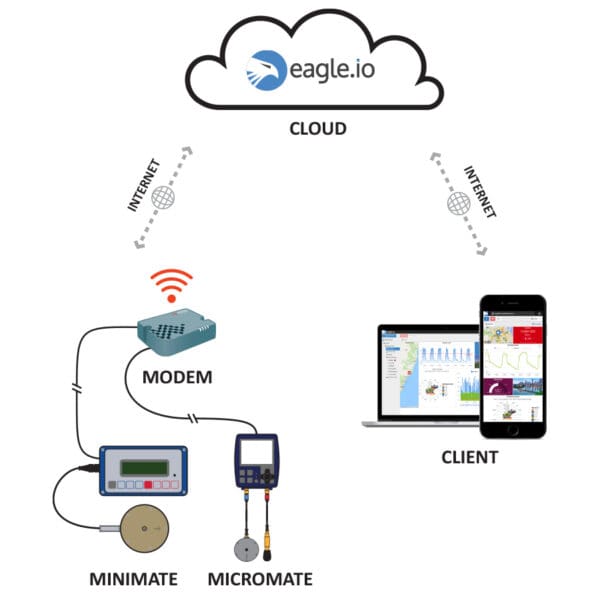

This is a quick introduction to new technology for machine condition monitoring with wireless vibration sensor and cloud system which can provide 24x7 data a. In addition Phantom sensors have a battery life that lasts between 3 to 6 years and are very easy to install.

This way RMS values can.

Ad Octopart offers price stock information comparison for electronic components. The Echo Wireless Vibration Monitoring System can safely look at the machines health several times per day and provide data to your existing vibration monitoring system. Monitoring these parameters help identifying early faults like imbalance bearing faults looseness misalignment and others. The multiplexer comes standard with eight channels but can accommodate over one hundred while also accepting virtually any type of sensor. You can closely monitor any piece of equipments static dynamic vibration analysis and differential process and vibration data from anywhere around the globe. It provides rich information about machinery health for both operations and maintenance personnel. With wireless vibration monitoring the sensor tracks and records vibration level measurements used to determine the health of rotating machinery such as compressors and pumps drive motors driven devices and belts gears shafts bearings and other components that make up a mechanical system. IOCL Supply Of Spares Of Wireless Vibration Monitoring System As Per Tender Specification Supply Of Spares Of Wireless Vibration M Due Date. Customized training for you andor your subcontractors.

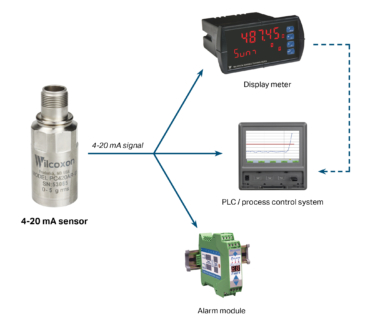

Wireless vibration monitoring systems use multiple vibration sensors tools and devices to take key vibration measurements. Overall vibration PeakVue measurements and temperature readings can be easily integrated into any control system or plant historian while. It is the only type of vibration and shock recorder that allows. A vibration monitoring system is a set of tools used to measure one or more parameters in order to identify changes in the behaviour of the machinery. It measures automatically vibration in three directions as well as the bearing temperature. Also our Wireless Vibration Sensor wake up on high vibration levels in order to send data and alarms. In addition Phantom sensors have a battery life that lasts between 3 to 6 years and are very easy to install.

Post a Comment for "Wireless Vibration Monitoring System"